Project Detail: The project included (3) basic items: Logistics Escape Trunk (L.E.T.), Cofferdam and L.E.T. Cradle. The basic size of the LET was 12 ft by 12 ft by 8’-6 high. The LET consisted of a structural steel frame with special honeycomb extruded aluminum sheeting panels on the walls. The construction techniques included fabrication of various wall, roof and floor subassemblies. The roof included a large sliding door (about 6 foot square). The extruded aluminum wall panels were approximetly 11 inches wide and a special extruded aluminum spline and riveted construction was used to join each of the adjoining wall panel sections. The wall panels were then riveted to the structural steel wall frames. The LET was completely shop assembled, finish painted and shipped direct to the Puget Sound Naval Shipyard in Bremerton, Washington.

The cofferdam is a 1” rolled plate fabrication with access openings and special flange requirements for interface of the LET with the hatch of the Seawolf class submarine. Various machining processes were used to maintain the tolerance requirements for interface with the submarine hatch.

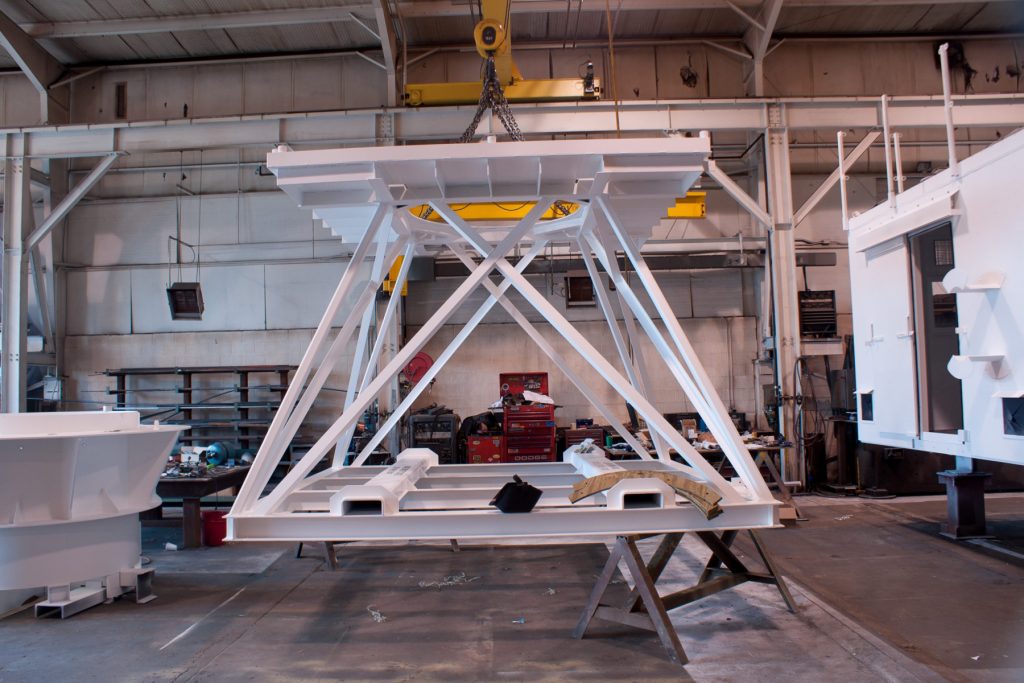

The Cradle was a structural framedesigned to store the LET and Cofferdam assembly. Dimensionally it was about 12 ft by 12 ft by 9 ft high. The Cradle was also provided with ladder access to the upper work platform area.

Project Record: HPS-GOV-007

This contract also included some miscellaneous items; Access stair and platform at each of the two entry doors into the LET. Stainless steel caged ladder approximetly 20 feet long.