Over the years HPS has provided a wide range of fabricated items to our client from small part carriers to complete salt bath furnace systems.In this record we will address a variety of the smaller fabricated items. If additional information or clarifications are required, please contact HPS.

BURNER TUBES: Burner tubes are a replacement part in our client’s furnace system; these burner tubes over time become worn and require replacement. Tubes are constructed of 3, 4 and 6” schedule 40 and 80 pipe and 180 degree pipe bends; materials of construction also include 304 stainless steel. Pipe sections are beveled and welded and each burner tube is pressure tested prior to shipment. The burner tube is weld to a mounting plate (3/4 to 1 ½”); serial number is attached to each burner tube mounting plate for identification and tracking. HPS completes about 100 burner tubes per year.

BURNER TUBES: Burner tubes are a replacement part in our client’s furnace system; these burner tubes over time become worn and require replacement. Tubes are constructed of 3, 4 and 6” schedule 40 and 80 pipe and 180 degree pipe bends; materials of construction also include 304 stainless steel. Pipe sections are beveled and welded and each burner tube is pressure tested prior to shipment. The burner tube is weld to a mounting plate (3/4 to 1 ½”); serial number is attached to each burner tube mounting plate for identification and tracking. HPS completes about 100 burner tubes per year.

BASKETS: Parts baskets are used to hold/handle a variety of parts that are used in a salt bath furnace. The furnace system is used to strip paint, scale and grease for production parts. The baskets are typically constructed using angle iron and round bar frame with expanded metal. Parts Baskets are also constructed using 304 stainless steel. Basket sizes vary from small, 12 inches square to as large as 8 foot by 6 foot by 5 foot tall. Size and materials of construction are dependant on the size and weight of the parts being handled.

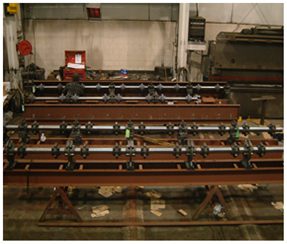

PARTS FIXTURES: Parts fixtures are used to hold a variety of parts that are used in a salt bath  furnace. The furnace system is used to strip paint, scale and grease for production parts. The fixtures are constructed of various steel shapes including channel, angle, bar and wide flange. Typically HPS will receive a sample of the part being handled in order to maximize the number of parts and insure the method of securely holding the part when moving the fixture in and out of the furnace.

furnace. The furnace system is used to strip paint, scale and grease for production parts. The fixtures are constructed of various steel shapes including channel, angle, bar and wide flange. Typically HPS will receive a sample of the part being handled in order to maximize the number of parts and insure the method of securely holding the part when moving the fixture in and out of the furnace.

SLUDGE PANS: Sludge pans are used in the bottom of a heated salt bath tank to collect the “sludge”. The pan is then removed from the salt solution, dumped and returned to the furnace for collection of sludge and waste material. These pans allow removal of sludge without the need to drain the salt solution from the tank. Construction materials include plate, bar and angle varying in size from 3/8” to ¾”. These pans are provided with a lifting bar (referred to as a bail) with a clamshell style pan for ease of dumping.